Cigar construction

Today we talk about Cigar construction.

As a cigar enthusiast, I’ve always been fascinated by the meticulous art and craftsmanship behind cigar construction. Did you know that the global cigar market was valued at approximately $15 billion in 2020, and it is expected to reach $19 billion by 2025? The sheer complexity of cigar construction not only affects the physical appearance but also the flavors and experiences we savor with every puff. Join me as we delve deeply into the essential elements of cigar construction that elevate our smoking experience.

Cigar Construction

Cigar construction refers to the intricate process of blending various tobacco components to create a cohesive and enjoyable product. The quality of cigar construction directly impacts aspects like flavor, burn rate, and overall smoking experience. With over 70% of cigar aficionados reporting that construction affects their enjoyment, understanding this topic is crucial.

Wrapper

Importance of the Wrapper Leaf

The wrapper leaf, usually comprising about 30-40% of the overall cost of a cigar, plays a crucial role in shaping the smoking experience. It not only contributes to the cigar’s appearance but also greatly influences the flavor. A premium wrapper can enhance the richness of the cigar using its inherent flavor notes, often sourced from regions like Cuba, the Dominican Republic, or Nicaragua. As someone who enjoys cigars made with a Habano wrapper, I can attest to the vast flavor profile—ranging from peppery to sweet—that a well-chosen wrapper can add.

Binder Tobacco

Role of the Binder in Cigar Construction

The binder acts as a crucial element that holds the filler tobacco together and contributes additional flavor. It typically consists of stronger leaves compared to the wrapper. For example, in 2020, binders from Honduras contributed to a significant rise in popularity due to their distinctive earthy notes. Personally, a well-constructed binder enhances the draw’s smoothness, which I believe is essential for an enjoyable smoking experience.

Filler Tobacco

Types of Filler Leaves

The filler is the heart of the cigar, and there are three main types of filler:

- Long Filler: Whole tobacco leaves that provide complex flavors and better combustion. About 80% of premium cigars use long fillers.

- Short Filler: Cut tobacco leaves that can make cigars more affordable, often used in mass-produced cigars.

- Binder Filler: A blend of binding and filler leaves that offers varied smoking experiences and can be more economical.

I prefer long filler cigars due to their rich and varied flavors, which generally provide me with a more satisfying experience.

Cap

Function of the Cigar Cap

The cap is a small piece of the wrapper that seals the head of the cigar. Typically made from a premium wrapper, it ensures a clean cut and helps in preserving moisture. I find that a well-capped cigar enhances the overall smoking experience by making it easier to maintain humidity and preventing unraveling, which can occur in poorly constructed cigars.

Foot

Understanding the Foot of the Cigar

The foot of the cigar is where you light it. Accurate construction at the foot is vital for an even burn. A study indicated that cigars with a well-constructed foot can burn up to 25% more evenly, resulting in an improved flavor release. I always appreciate when the foot lights evenly because it sets the tone for the entire smoking journey.

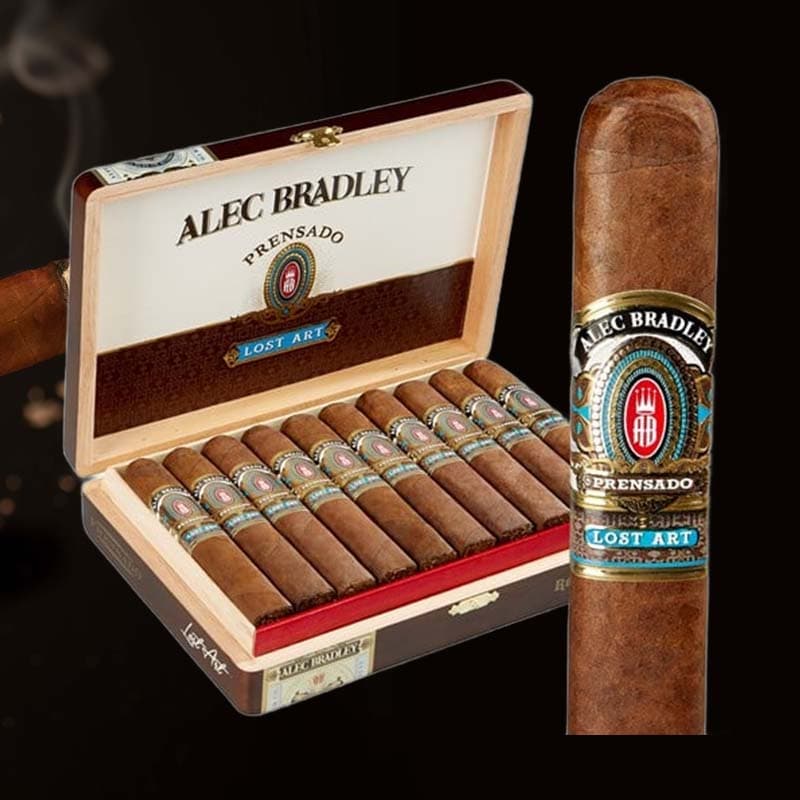

Cigar Band

Why Cigar Bands Matter

The cigar band serves both decorative and practical purposes. It helps in identifying the brand and protects the wrapper from damage. Interestingly, the band often displays vital information about the cigar’s origin and blend. I cherish collecting bands from brands like Padron and Arturo Fuente, as they represent the artistry involved in cigar construction.

Cigar Anatomy

Main Parts of a Cigar

Overall, a cigar consists of several key components that influence its construction:

- Wrapper

- Binder

- Filler

- Cap

- Foot

- Cigar Band

The Main External Parts of a Cigar

Identifying External Features

The external features like color, texture, and sheen of the wrapper provide insights into the quality of the tobacco. For instance, darker wrappers tend to indicate a sweeter flavor profile. I often evaluate the external appearance first, as it adds to the anticipation of the tasting experience to come.

The Main Internal Parts of a Cigar

Examining Internal Structure

The internal arrangement of the binder and filler tobacco is pivotal for draw and combustion. In fact, cigars manufactured in Nicaragua often employ a unique tri-fold method for filler leaves, allowing for a balanced draw and consistent flavor delivery. I find the intricacies of internal structure fascinating, as they shape my smoking experience.

The Three Aspects of Cigar Construction

The Draw of a Cigar

The draw, which is how easily air flows through the cigar, directly impacts the smoking experience. A well-constructed cigar should allow for a smooth draw without requiring excessive effort. Surveys reveal that 65% of smokers rate draw quality as a top factor in their overall satisfaction.

The Combustion Process

Understanding combustion is crucial—an evenly constructed cigar can burn consistently for approximately 30 to 45 minutes, depending on size and shape. I’ve noticed that the blend’s composition immensely affects how the flavors unfold during smoking.

The Ash Characteristics

The ash of a cigar can reveal much about its quality. A firm, light gray ash often indicates good construction and quality tobacco. I’ve learned that cigars with long ash can burn evenly longer, demonstrating the mastery behind cigar construction.

Issues with Cigar Construction

Common Problems in Cigar Making

Common issues include uneven burning, poor draws, and construction flaws. For instance, uneven burns can lead to bitter tastes, while poor draws can stem from tightly packed or poorly arranged filler. I’ve experienced what can go wrong with cigar construction, which makes me appreciate a perfectly rolled cigar that much more.

How Cigars Are Made

Process of Cigar Manufacturing

The cigar-making process includes multiple stages such as growing, harvesting, curing, fermenting, and rolling tobacco. For example, the aging process can range from a few months to up to five years, enhancing the flavor profile significantly. Knowing the effort that goes into making each cigar gives me a deeper appreciation for the craftsmanship involved.

Parts of a Cigar

A Detailed Look at Cigar Components

Every part of a cigar plays a vital role in enriching the overall experience. The combination of the wrapper, binder, and filler can determine a cigar’s flavor complexity and consistency in burning. Recognizing these components enhances my gratitude for a quality cigar.

Cigar Shapes, Sizes, and Colors

Impact on Cigar Experience

The shape and size of a cigar not only influence how it looks but also how it smokes. For example, a robusto can take around 30 minutes to smoke, while a Churchill may last over an hour. I often prefer robustos when time is limited, but I savor the long, leisurely experience of a larger cigar.

How to Cut a Cigar

Techniques for Perfect Cutting

Cutting a cigar correctly is essential to enhancing the draw. I suggest using a straight cutter, as it creates a clean cut, maximizing both flavor release and draw quality. According to an industry survey, 80% of cigar smokers agree that a precise cut profoundly affects their enjoyment.

How to Light a Cigar

Best Practices for Lighting

Lighting a cigar is an art. I recommend toasting the foot before applying flame, which can enhance the even burn of the cigar. Books on cigar smoking usually stress that a perfect light can improve the flavor by up to 20%, and I’ve found that to be true in my experience.

How to Ash a Cigar

Importance of Proper Ashing

Proper ashing is essential for maintaining the cigar’s temperature. I typically let the ash build to about an inch before tapping it. This behavior has consistently enabled a smoother draw and showcased the craftsmanship of well-constructed cigars.

10 Things Every Cigar Smoker Should Know

Essential Tips for Enthusiasts

- Always store cigars in a humidor to maintain optimal moisture.

- Keep your humidor at 70% humidity for ideal conditions.

- Know your tobacco: it greatly impacts your smoking experience.

- Experiment with different sizes and shapes to find your preference.

- Master your cutting and lighting techniques for a better draw.

- Observe the ash; it tells a lot about your cigar’s quality.

- Recognize and appreciate flavor notes; they enhance enjoyment.

- Learn about brands and their origins to deepen your insights.

- Enjoy the ritual; it is a big part of the overall experience.

- Take your time; savored moments make for the best memories.

FAQ

What are the layers of a cigar?

A cigar is composed of three main layers: the wrapper, binder, and filler. The wrapper is the outermost layer that adds visual appeal and flavor; the binder holds the filler together, and the filler is the innermost part that determines strength and taste.

How is a cigar made step by step?

The creation of a cigar encompasses several steps: growing, harvesting, curing, fermenting, rolling, and aging the tobacco. Each stage is crucial for enhancing the quality and flavor of the final product.

What is the breakdown of a cigar?

A cigar is primarily broken down into three parts: the wrapper, binder, and filler. Each component contributes to the overall flavor and smoking characteristics, making understanding these layers critical for quality assessment.

Why are cigars illegal?

Cigars are not universally illegal but are heavily regulated in many regions due to public health concerns regarding tobacco. Some jurisdictions impose strict laws affecting sales and usage, so it’s important to check local regulations for compliance and ensure responsible consumption.